Currently, the companies that deal with the fabrication of products parts consistently and in large quantities are under pressure. This is because such firms are expected to come up with innovative product and designs and also ensure that they became successful with their products within the stipulated time. To this end, a plastic injection molding chicago il process helps you to deal with a lot of issues that are involved in the production stages, thus elevating your venture to the next level.

Currently, the companies that deal with the fabrication of products parts consistently and in large quantities are under pressure. This is because such firms are expected to come up with innovative product and designs and also ensure that they became successful with their products within the stipulated time. To this end, a plastic injection molding chicago il process helps you to deal with a lot of issues that are involved in the production stages, thus elevating your venture to the next level.

What Is Injection Molding?

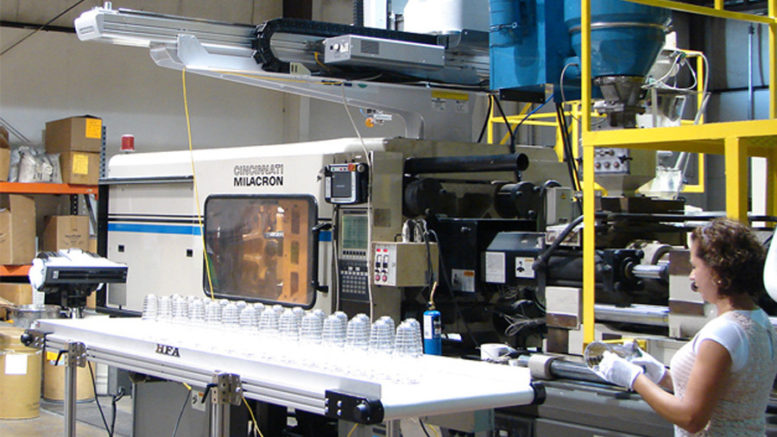

In simplest terms, plastic injection can be said to be the process of coming up with single parts in large quantities. In most cases, this type of production is applied where the producer wants to come up with similar parts but in large quantities, perhaps thousands or even million pieces. The greatest advantage of using this type of production in any firm is that it helps you to scale your production mass and the cost. This implies that once the initial cost of production is met, then the production per unit during mass production is considerably low. Additionally, as the mass production increases the production coast continues to drop.

Injection Molding Produces Low Scrap Rates

In most cases, the traditional production measure of using machining is associated with wastage of raw materials as some substantial amount of the material is cut and wasted. This is an evident challenge when dealing with the production of additives like 3D production. Although there is also some wastage in the injection molding approach, the wastage from this model comes from four major parts, which include the gate location, sprue, runners, and from the overflow. This condition is normally referred to as the flash.

Injection Modeling Is Repeatable

The first product that is produced from this approach will automatically be equal in all dimension to the last product that is produced from the same model. This implies that this approach is vital when producing products that need to be equal in size and shape. This makes injection modeling the best practices when it comes to the production of products that require a lot of consistency, be it in size or volume.

The Downside To Injection Molding

Just like any other production approach, injection modeling also has its challenges. For instance, it’s upfront cost is relatively higher due to tool requirements, designing, and testing. For you to come up with the right design and specification of mass production, you need to ensure that you have all the requirements set right from the initial stages.

However, this is not always as simple as it sounds. This is because setting the stage right for mass production involves many steps which can be broken down to the following. First, designing of the initial product, designing the injection model and the refining any faults that might be available. However, in all aspects, injection modeling is one of the most effective ways of producing plastics products in mass production.

Be the first to comment on "Everything You Need to Know About Injection Molding"